At PMI, we are driven by our core values:

TRUST, KNOWLEDGE, TEAM WORK, TRANSPARENCY, RESPECT & QUALITY

PMI (Production Modeling India) is an Operations Consulting Firm founded in 2006 as the Indian arm of PMC (Production Modeling Corporation). It has been providing Operations Improvement services to its clients for over 32 years. Over the last 16 years, PMI has completed several Industrial Engineering and Simulation projects in India and around the world for various industry sectors, including Automotive, Auto components, Two Wheeler, Pharma, Steel, and Service. The PMI team is growing steadily, with more experienced and enthusiastic consultants selected and trained through our unique processes. PMI’s vision is to be a full-service engineering consulting firm providing high ROI solutions to clients across the globe.

Happy Clients

Projects Completed

Years of Experience

A team is as strong as its team members. At PMI, we have an excellent mix of young, enthusiastic as well as senior experienced, and seasoned engineers with Domain knowledge. The total combined experience of the PMI team is more than 100 years ...

One Stop Shop - for all your Industrial Engineering and Simulation requirements

Over 100 years - of combined team experience across Shop floor, Consulting, Training and Management

Excellent mix - of Experiences and Seasoned Professionals as well as young, energetic and enthusiastic engineers

Our dedication - to I.E Services gives you the confidence to increase your production, productivity, profits and move your business forward.

Our team is your team - dedicated to reducing your effort, restraining your costs, responding to your problems, and anticipating your needs.

It's like having your own Industrial Engineering Team – at a fraction of the cost

Our Services

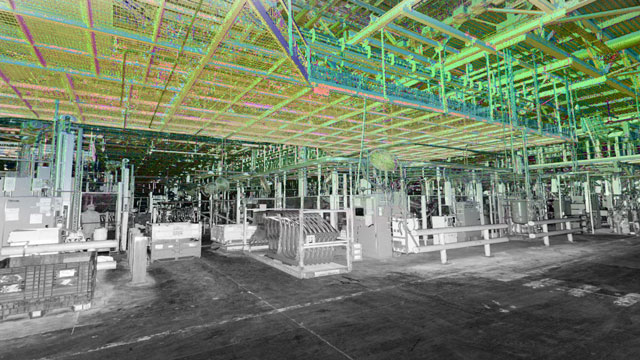

Reality Capture & CAD Services

Industrial Engineering Services

Simulation Modeling

Services

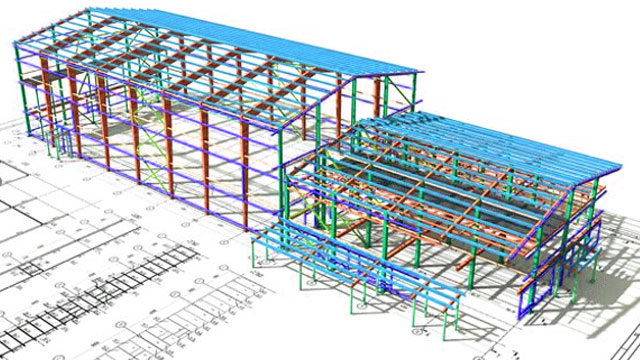

Steel Detailing Services

GIS Consulting Services

Advanced Software

Let our experts show you how we can support your projects!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!

Want to schedule a time to speak with one of our representatives NOW?